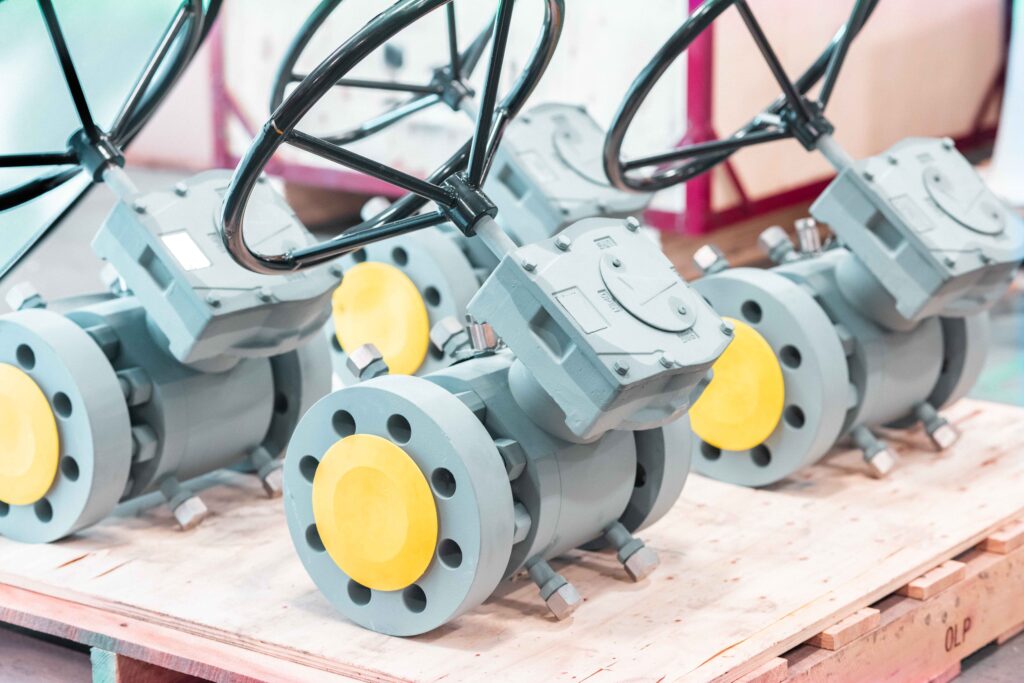

Your Guide to the Different Types of Ball Valves

Ball valves are a critical part of industries including oil and gas, manufacturing, chemical, and water treatment. They even have residential uses.

With so many different applications, it’s not a surprise to find many different types of ball valves. These include trunnion ball valves, welded ball valves, a metal seated ball valve, and more.

How do you find the right valve for your project?

Find out more about the different types of ball valves. You’ll have the information you need to choose the best ball valve for your application.

Features of Ball Valves

Several types of ball valves are available, but they all have some features in common. A ball valve is a quarter-turn shut-off valve. It controls the flow of a liquid or gas.

Ball valves are well-suited for applications with high pressure, high temperatures, and high volume. They open and close quickly. They’re less prone to corrosion and damage than other types of valves.

Parts of a Ball Valve

The main parts of a ball valve are the body, the ball, the seats, and the stem.

The valve body is the primary part of the valve. It contains all of the components to turn the valve on and off.

The ball is a rotary ball with a hole (bore) in the center. Turning the ball 90º will either let the liquid or gas flow through or stop it from flowing.

The seats are discs between the body and the ball. They support the ball and make a seal between it and the body.

The stem connects the ball to an external control mechanism like a handle or lever. Turning the stem turns the rotary ball to open and close the valve.

Types of Ball Valves

The different types of ball valves can be classified based on different features. These classifications are based on factors like:

- Number of ports

- Body assembly

- Materials

- Ball design

- Bore size

The versatility of ball valves is one of their main advantages.

Number of Ports

A ball valve can have two, three, or four ports. Most ball valves are 2-way with an input and an output.

A 3-way valve is either L-shaped or T-shaped. 3-way valves change the flow direction. They let you distribute or mix flows.

4-way valves can be L, T, or X shaped. An X (LL) port has the four ports evenly spaced around the valve chamber. It has two flow positions and a central position with all the ports closed.

Body Assembly

The valve housing is either a one-piece, two-piece, or three-piece assembly. Threaded connections or bolts usually hold together assemblies with multiple parts.

One, Two, and Three-Piece Assemblies

A one-piece has the body and end connections made from a single piece of material. You can’t open it for cleaning or maintenance. One-piece assemblies are the most economical option.

You can take the two parts of a two-piece assembly apart for inspection and maintenance. You have to remove it from the pipeline to separate the parts, though.

Three-piece assemblies are the most expensive. You can work on the valve without removing it from the pipeline.

Welded Ball Valves

Fully welded ball valves have a body made from forged parts welded together. This design doesn’t have joints, which leaves fewer possible leak paths.

Fully welded ball valves are more compact. They’re stronger but also lighter.

Many welded ball valves use butt welds. This type of weld gives complete fusion and high strength.

Materials

You can find ball valves made from several different types of materials. The material for the valve body, ball, and seats are important to consider when choosing a ball valve.

Valve Body and Ball

Common materials for valve bodies include:

- Stainless steel

- Brass

- Bronze

- Cast iron

- Aluminum

- PVC

- CPVC (chlorinated PVC)

The choice of material depends on the conditions the valve will be operating in. Common materials for the flow control ball include stainless steel, brass, chrome-plated steel or brass, and PVC.

Soft Seated and Metal Seated Ball Valve

The valve seats can either be thermoplastic or metal.

Soft seated ball valves use a flexible thermoplastic seat material like PTFE. They provide a very tight seal. They aren’t suitable for abrasive or dirty fluids, though.

Metal seated ball valves will withstand severe service conditions. You can further harden metal seats with coatings like chromium carbide and tungsten carbide.

Ball Design

Ball valves use two types of designs to hold the ball in place. Most ball valves use a floating ball. Trunnion ball design is also an option.

Floating Ball Valves

In a floating ball valve, the ball is suspended in the liquid or gas media. Cupped valve seats support the ball. Two sealing rings hold the ball in place.

Trunnion Ball Valves

Trunnion ball valves support the ball on the top and bottom. The ball attaches to the stem on one end and a shaft (the trunnion) on the other end. The additional support reduces the load on the seat rings.

Trunnion ball valves are a good option for large diameter valves or high-pressure environments.

Bore Size

The hole through the ball can have several different shapes. The type of bore affects how the ball valve operates.

Full Port

A full bore design has a bore diameter the same as the pipe. It reduces friction loss and is easier to clean.

Standard Port

A standard bore ball valve has a smaller port and ball than a full port design. Standard port ball valves restrict the flow somewhat. However, they’re less expensive.

Reduced Port

Most ball valves have a reduced bore design. The flow area is smaller than the pipe. These types of ball valves create friction losses.

The friction loss is still small compared to other types of valves, though.

V-Shaped

A v-shaped hole in the ball or in the shape of the seat lets you control the flow rate more precisely. The flow characteristic is almost linear. V-shaped ball valves are well-suited for applications with a high flow rate. They provide a minimal drop in pressure and a tight shutoff.

Finding the Best Ball Valves

The best ball valve is the one best suited to your application. With all of the options, it can seem challenging to find the right ball valve for your project.

Whether you need trunnion ball valves, welded ball valves, or another type, Anything Flows has what you’re looking for. We offer the highest quality flow control solutions and superior customer support. You can be confident buying ball valves online from our catalog.

Contact us today for more information about our selection of ball valves. We’ll work with you to find the best valve for your application.